ONDUCLAIR

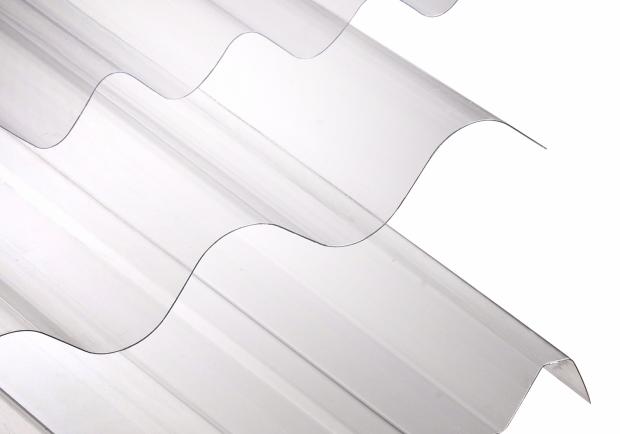

Gün ışığı geçirgenliğine sahip, şeffaf çatı kaplama sistemi

Açıklama

Ürün Avantajları

Özellikler

ONDUCLAIR‘in üstün ışık geçirgenliği, uygun bir ortamda görsel açıdan konfor ve verimlilik yaratır.

Saydam tip polikarbonat levhalar üstün kaliteleriyle %90 ışık geçirgenliğine olanak verir ve bu özelliğini yıllar boyu korur. Polikarbonat 10 yıl yaşlandıktan sonra bile %80 ışık gerçirgenliğine sahiptir.

Darbe dayanımı yüksektir, 135 m/s hızla çarpan dolu etkisiyle tahrip olmaz.

30 C ile +130 C arasındaki sıcaklıklarda kullanılabilir.

Polikarbonat UV (ultraviyole) ışınlarını geçirmez.

Işık geçiren levhalar üretiminde 50 yıllık deneyim.

Storage

The polycarbonate sheets should be stored on pallets in a covered and ventilated place.

Installation and Security

During installation do not step on the sheets, the breakable sheets security instructions should be applied.

Resistance to Impact From Inside

Polycarbonate sheets are impact resistant. Howeever when used in buildings like sport halls, an extra surface protection is required.

Installation on the Roof

General Guidelines for Battens:

Steel box profiles

Maximum width: 40 mm

Maximum thickness: 1,5 mm

Wooden

Maximum width: 60 mm

Maximum height: 80 mm

The span between battens should be choosen in the following table. These valors are calculated in order to give three times security to the breakability and for a sheet displacement lesser then 1/100 of the span

During the installation the corrugations must be layed parallel to the pitch and the sheets should be installed in a direction opposite to the prevailing wind.

Cutting

The sheets can be cut with a thin teeth (5 teeth/cm) hand saw or spiral power saw.

Laying Direction

The corrugations must be layed parallel to the pitch.

Widthwise Installation

The sheets should be installed in a direction opposite to the prevailing wind and the overlaps should be protected against the wind.

Lenghtwise Installation

The laying must always start from the eaves. The overlap of each consecutive raw should cover the preceeding sheet.

Lenghtwise Overlapping

The overlapping must be done on top of the batten and the overlapping lenght should be at least of 150 mm for all type of profiles.

Widthwise Overlapping

The overlapping should be done in a direction opposite to the prevailing wind.

G.O.:

-Protected or normal area; half corrugation

-Windy area: 1.5 corrugation

PC.: Follow the application instructions for ONDULINE HR sheets.

P.O.: 1,5 corrugations

S.P.: 2 corrugations

H3.: 1 corrugation

Fixing

The sheets are fixed on top of the corrugations on the roofs and inside of the corrugations for wall cladding with screws or tirephons.

The holes should never be opened on a distance less then 50 mm from the edge of the sheets. The holes are opened with a power driller and the hole diameter should always be 4 mm larger then the fixing device diameter. The surrounding of the hole should be cleaned from all dirts such as dust, drilling residues, etc. for proper application of the washer and gaskets.

While use with fibre-cement sheets take all precautions to prevent the chemical diffusion of alkaline which may cause cracks and mechanical deformation on the sheets. The screws should be fixed in order to prevent all leakages but also to let the sheets dilate. The sheets must never be nailed. The use of rivet and nailing is prohibed (1).

(1) Except for the HR profile used together with ONDULINE HR sheets as skylighting purposes

Special Fixing Parts

Precaution should be taken against wind at faces (like gable wall end) by using L profiles.

Fixing Devices

Fixing devices and accessories should be choosen from products made within the international quality standarts in order to give the minimum mechanical strenght, leakage resistance and durability. The staggered sheets should be fixed on each batten on top of the corrugations. In addition the sheets should be screwed in the middle of the batten

on widthwise overlapping. The use of tapping screws. is recommended. The screws should be fixed together with the gasket and the space under the corrugation should be filled to prevent any damage to the corrugation.

Anti - Leakage

If the slope is 25 % or less slicone mastic or double sided self sticking butyl stripe should be used between overlappings on both sides to prevent any leakages.

On lenghtwise overlaps zig zag installation is recommended for the drainage of the humidty drops which may be caused by condensation.

Ventilation

The general guidelines for ventilation is the same as the actual standart regulations. The use of polycarbonate sheets may cause temperory condensation regarding the climate and humidity conditions. Direct ventilation arrangements is mandatory on roofs and eaves or on top or bottom of the wall claddings. The ribs of the sheets should never be closed for proper ventilation.

The under-side of the sheets used for skylight purposes should be ventilated in order to not exceed 130C. The ventilation surface (air entry and exhaust) should be equal or more then 1/500 of the roof surface. (At least 380 cm2/ml)

Vault Roofs

Polycarbonate sheets can be used also on curved surfaces. The minimum radius: h X 200. On installation the direction of the corrugation should be parallel to the curved surface. In order to align perfectly the sheets the installation of the battens should be linear to the curve

For vault roofs:

Vault roofs

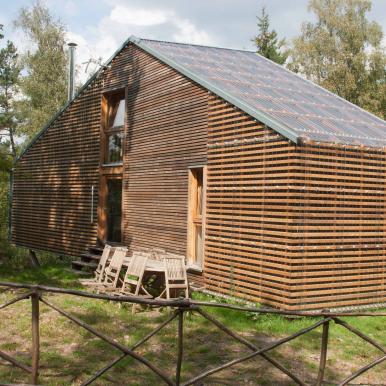

Wall Cladding

ONDUCLAIR polycarbonate sheets can be used both for vertical or horizontal wall cladding. The maximum accepted vertical deviation angle is 15 in siding surfaces. The corrugations should be installed parallel to the slope or vertical to the side. The sheets should be protected from the external effects or against collision by starting the cladding 1.50 m higher then the ground.

Overlaps

Lenghtwise Overlapping lenght should be at least of 100 mm for all type of profiles. For Widthwise Overlapping keep the same installation rules of roofing.

Dilatation

While fixing top or bottom sides never use flange on facade of the sheet, leave 10 mm of space with water leakage and ventilation precaution.

Lenghtwise Overlapping

The overlapping must be done on top of the batten and the overlapping lenght should be at least of 300 mm for all type of profiles. Avoid lenghtwise overlap on the ridge to prevent any water leakage.

Double Layer Installation

The ONDUCLAIR polycarbonate sheets can be installed in double layer with a minimum space of 60 mm between the sheets for proper ventilation.

Finally the reaction of the Polycarbonate sheets against acids and bases is satisfactory. In addition it is resistant to gypsum and cement elements used in the buildings and to mineralized air. The mould, moss, micro-organisms and the rodents have no effects on the quality of the sheets. However it is better to avoid the contact with the solvents.

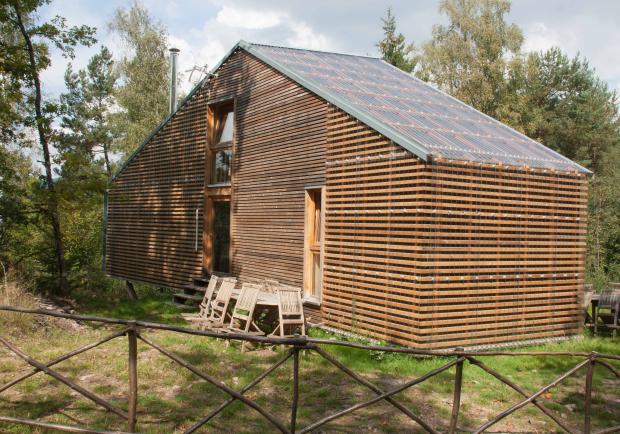

High-level, sustainable natural day light for the buildings

ONDUCLAIR provides long term sustainable optical performans through the UV protection layer.

Resistance to extreme air temperatures

ONDUCLAIR can resist extreme temperatures changing between +130° and -30°C. That’s how it can be applied to many geographical areas around the world.

Resistance to impact and hail

ONDUCLAIR doesn’t get broken under ordinary usage conditions. It can be applied very practically, so it is suggested for sports facilities and areas which are affected by hail regularly (Please see Application Guidlines).

First class fire evaluation

ONDUCLAIR’s applicability on different types of roofs and fire resistance is approved by Euroclass B-s1, d0.

Physical and Chemical Features

Polycarbonate sheets act conventiently to acids and alkalines. They are also durable to plaster and cement used in the buildings. They show resistance to salty air. Algea, mold, microorganisms and rodents don’t have effect on the qualities of the sheets. However, polycarbonate shouldn’t be contacted with resolvent materials.

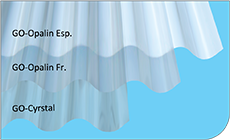

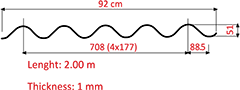

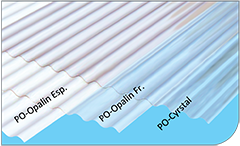

GO adapted for use with fiber

cement corrugated sheets.

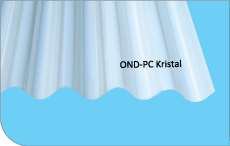

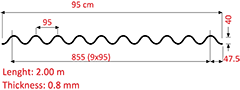

PC Crystal have the same dimensions

as ONDULINE HR sheets and are totally

compatible with its ondulations profile.

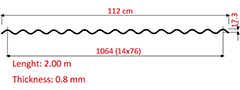

PO for use with Gl (galvanized iron)

sheets.

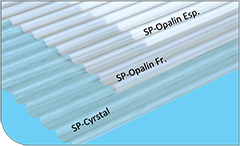

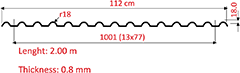

SP for use in greenhouses or aesthetical

lean-to-roofs.

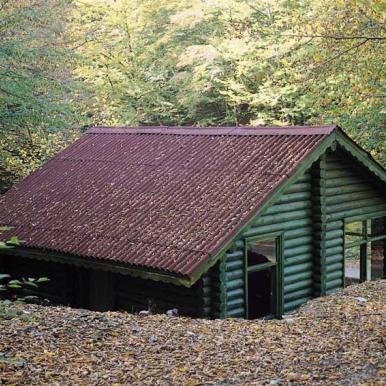

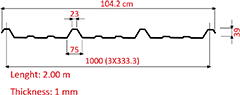

H3 for industrial buildings covered

with trapezoidal profiled sheets

Uygulama Alanları